The test for Determination of occupational noise exposure levels in public, residential and industrial areas provides useful information to determine priority noise control solutions

Overview of the Test for Determination of occupational noise exposure levels in public, residential and industrial areas

Test name: Acoustics – Determination of occupational noise exposure levels – Engineering methods.

Test Method:

ISO 9612:2009: Acoustics – Determination of occupational noise exposure – Engineering method [1].

Conducted at: public, residential and industrial areas

1. Test target and subjects

– Test target

This standard specifies an engineering method for measuring workers’ exposure to noise in a working environment and calculating the noise exposure level. This standard deals with A-weighted levels but is applicable also to C-weighted levels. Three different strategies for measurement are specified. The method is useful where a determination of noise exposure to engineering grade is required, e.g. for detailed noise exposure studies or epidemiological studies of hearing damage or other adverse effects.

The measuring process requires observation and analysis of the noise exposure conditions so that the quality of the measurements can be controlled. This standard provides methods for estimating the uncertainty of the results.

This standard is not intended for assessment of masking of oral communication or assessment of infrasound, ultrasound and non-auditory effects of noise. It does not apply to the measurement of the noise exposure of the ear when hearing protectors are worn.

The results of measurements carried out in accordance with this standard can provide useful information when defining priorities for noise control measures.

– Test subjects

Construction workers – mechanics, factory workers, workers must be exposed to noise in the working environment…

– Experimental methods

This standard provides three measurement methods used to determine noise exposure in the workplace:

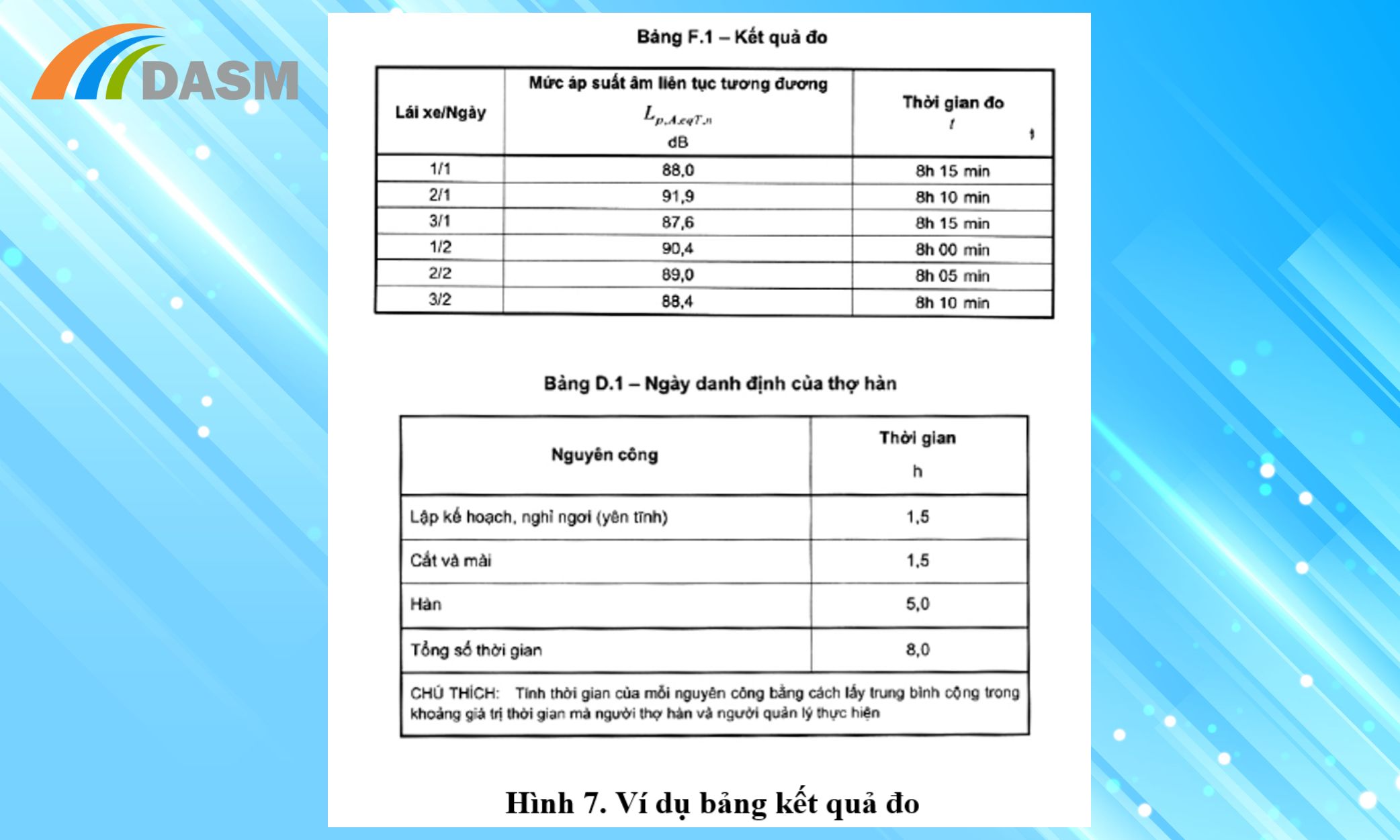

- Task measurements: analyze the work performed during the day and divide it into a number of representative tasks, and for each task separating measurements of the sound pressure level (see Clause 9);

- Job measurements: take random samples of sound pressure levels during the performance of individual tasks (see Clause 10);

- Daily measurement: continuous measurement of sound pressure level over complete working days (see Clause 11); Detailed instructions on choosing a measurement method are given in Appendix B.

– Work analysis

Work analysis is required for all situations. This analysis provides all the information needed to:

- Describe the activities of the enterprise and the work of the employees;

- Identify groups uniformly exposed to noise (see 7.2), if appropriate;

- Determine the nominal day or days for each employee or group of employees;

- Identify the tasks required to perform the profession, if appropriate;

- Identify potential noises;

- Choose the measurement method;

- Plan measurements.

- Job analysis requires attention to production, processes, organization, workers, and activities.

Measurements can be made using task-based, job-based, and daily measurement methods. Whichever measurement method is used, it is important to identify all significant noise sources and ensure that these are taken into account in the measurement plan.

2. Experimental procedure

Steps:

- Prepare and arrange equipment, microphones…

- Determine microphone placement.

- Perform sample measurements.

- Process and report results

3. Measurement uncertainty

– Mechanical impact on the microphone

Measurement errors due to mechanical impacts on the microphone can be avoided by not touching or impacting the microphone or windscreen. This effect is difficult to observe when using a personal meter to measure sound exposure levels. Many measuring devices record high sound levels if the microphone and/or connecting devices are touched, rubbed, or exposed to other objects.

Uncertainty of the results should be checked by comparing detailed measurement results (recorded) when available and observations made during the measurement (e.g. recorded in a notebook). If unknown peak values occur, need an investigation to determine their influence on the measurement results and it is necessary to re-measure if the influence is significant. In cases where a device without a recording function is used and the peak value cannot be interpreted, a re-measurement is required.

– Wind and airflow

Measurements should be avoided where the airflow has high velocity but if not, it should be avoided to keep noise to a minimum. If possible, the effect of airflow should be checked by measuring at a location with similar wind speed but without air flow. If this is not possible, this noise can be assessed at a location with similar wind levels but no occupational noise.

Airflow noise can be reduced by using a microphone with a wind shield. For personal sound exposure meters, the size of the windscreen is often limited. When using a hand-held sound level meter with a larger wind shield, the potential impact of airflow noise can be significantly controlled.

It is necessary to equip a wind shield with a minimum diameter of 60mm for the handheld sound level meter to reduce the influence of noise caused by air flow or wind.

Note: The contribution of wind and airflow depends on wind speed and wind hood size. For a wind hood with a diameter of 60mm or larger, the A-weighted sound pressure level of about 80dB is usually not much affected by wind speed above 10m/s.

– Added sounds

Note that to determine sounds related to noise exposure. Noises such as radios, voices, and signals will be considered relevant noises if the work analysis shows that they are part of the normal work situation. However, if the person making the measurements has good reasons to consider these noises as irrelevant, they may be eliminated from the measured data, provided this is reported.

If unusual phenomena are observed in the workplace during measurements, possible effects on the results of the measurements should be evaluated. If this effect is significant, new measurements shall be carried out.

The role and importance of the Test for Determination of occupational noise exposure levels in public, residential and industrial areas

The test for Determination of occupational noise exposure levels in public, residential and industrial areas conducted by the Institute for Development & Application of Acoustic Materials helps meet the needs of:

- Identify priority measures to control noise, prevent noise, isolate noise sources, and implement mitigation measures to to avoid health and safety risks and not have negative impacts on the community.

- Provides useful information for epidemiological studies on hearing damage.

- Predict long-term risks of hearing loss for workers.

- Measure the working environment and assign appropriate work. Train workers exposed to noisy environments to clearly understand the harmful effects of noise and safe working measures.

- Support legal disputes, litigation, soliciting inspections, measuring and analyzing environmental samples in case of noise violations exceeding technical environmental regulations.

In the past, if you still had some concerns and wonders about spending a lot of money for similar acoustics services abroad, now you just need to contact with DASM. We will proactively carry out the entire remaining process in the fastest possible time to perfect the customer experience with us: DASM provides acoustics consulting services with truly outstanding quality and the most competitive fees in the industry along with excellent customer service policies.

Meaning of acoustic testing service at DASM

Today, globalized commercial life creates countless new markets and sources of supply across the world. To walk along them would be international regulations and standards to help customers easily assess the quality – trace the product’s origin, choose suitable / superior products. In particular, they also support manufacturers to constantly improve and better technology, techniques, materials, production methods, sales, etc.

The Institute of Development & Application for Sound Materials (DASM) is a pioneering, comprehensive, professional and prestigious brand in Vietnam in the field of acoustics. On January 12, 2023, DASM was granted a certificate No. 114/TĐC – HCHQ by the Directorate for Standards, Metrology and Quality (Ministry of Science and Technology) on certification of testing activities registration for multidisciplinary synthesis in the field of Mechanics (registration number: 707/TN – TDC).

Our acoustic testing services help customers get accuarate practical results which meet sustainability, standard performance. We also offer solutions – consulting – adjusting designs … to optimise products and services. As a result, you will update, meet and adapt to ever-changing international standards to break through in revenue, profit and elevate your brand.

If you want to perform a test for Determination of occupational noise exposure levels in public, residential and industrial areas, please contact the Hotline for detailed advice!